+27(0)10 594 4644

Supplier of world leading 3D Printer brands

All Stores

Solve big problems with large-scale parts.

Or print multiple parts in one job, so you can accelerate product development or keep production running.

Build Volume

4.6x

Larger build volume compared to Form 4

Form 4L

353 x 196 x 350 mm

(13.9 x 7.7 x 13.8 in), 24.2 L

Form 4

200 x 125 x 210 mm

(7.9 x 4.9 x 8.3 in), 5.2 L

Speed at scale. Large prints in under 6 hours.

.png)

.png)

.png)

Stunning parts that always fit.

.png)

Sharpest Details

Highly collimated light and 46 µm pixel size with pre-tuned anti-aliasing for sub-pixel resolution.

Smoothest Surfaces

Lower peel forces, Light Touch Supports, and 46 µm pixel size with pre-tuned anti-aliasing.

Most Accurate Assemblies

±0.15% XY dimensional tolerances so assemblies always fit.

.png)

Learn to print in four simple steps:

So intuitive that anyone can learn to print in 15 minutes.

1. Import your model and prepare your print.

-

Smart auto-orientation

-

Advanced support generation

-

Live printability checks

2. Load a material and click print.

-

Validated print settings

-

No-hassle cartridge and tanks

-

Automatic resin dispensing

3. Remove, wash, cure.

-

Quick release part removal*

-

Automatic part cleaning

-

Precision post-curing for peak material properties

-

*Build Platform Flex L is not yet available. Coming soon.

4. Finish your part.

-

Light touch supports for quick, clean support removal

-

Optional sanding, coating, or painting

-

Unmatched optical power: 16 mW/cm² delivered to the print plane.

-

Plano-convex lens array and optical baffle: Creating highly collimated and uniform light, even at high power.

-

Extremely long lifetime, due to an integrated cooling system.

The Backlight Unit generates a uniform area projection of an ultra-high power light using 145 LEDs and collimating lenses. It cures resin quickly and precisely, delivering blazing fast print speeds with excellent print quality and accuracy anywhere on the build platform.

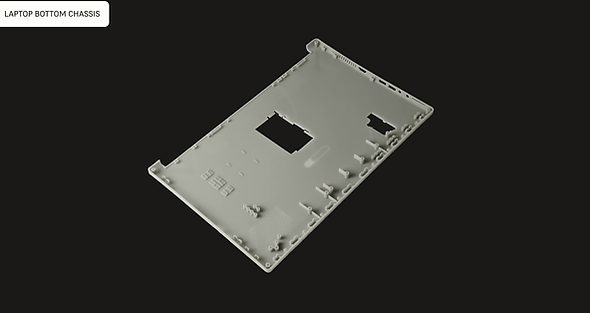

A wide range of applications to help you excel in your work.

.png)

Pre-Production Validation

Tough 1500 Resin

Forge Motorsport reverse-engineered an underperforming part, 3D printed a new design, and tested it on a vehicle for five months before committing to tooling.

.png)