3D Printing Technology Comparison: FDM vs. SLA vs. SLS

- BuildVolume Admin Team

- Nov 30, 2019

- 3 min read

Additive manufacturing, or 3D printing, lowers costs, saves time, and transcends the limits of fabrication processes for product development. From concept models and functional prototypes in rapid prototyping to jigs, fixtures, or even end-use parts in manufacturing, 3D printing technologies offer versatile solutions in a wide variety of applications.

Over the last few years, high-resolution 3D printers have become more affordable, easier to use, and more reliable. As a result, 3D printing technology is now accessible to more businesses, but choosing between the various competing 3D printing solutions can be difficult.

Which technology is suitable for your particular application? What materials are available? What equipment and training do you need to get started? How about costs and return on investment?

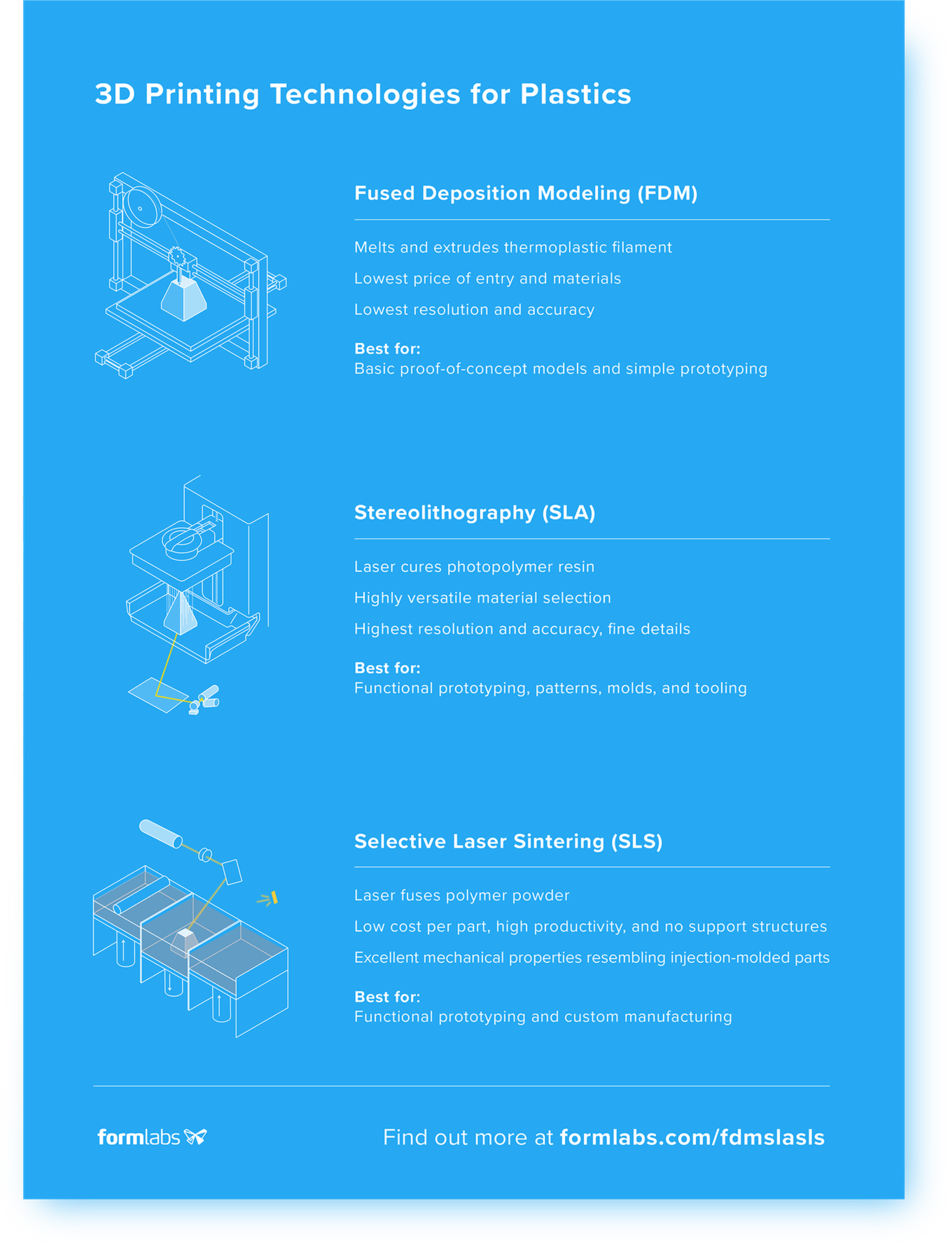

In this article, we’ll take a closer look at the three most established plastic 3D printing processes today: fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS).

Fused Deposition Modeling (FDM)

Fused deposition modeling (FDM), also known as fused filament fabrication (FFF), is the most widely used form of 3D printing at the consumer level, fueled by the emergence of hobbyist 3D printers. FDM 3D printers build parts by melting and extruding thermoplastic filament, which a printer nozzle deposits layer by layer in the build area.

FDM works with a range of standard thermoplastics, such as ABS, PLA, and their various blends. The technique is well-suited for basic proof-of-concept models, as well as quick and low-cost prototyping of simple parts, such as parts that might typically be machined.

FDM parts tend to have visible layer lines and might show inaccuracies around complex features. This example was printed on a Stratasys uPrint industrial FDM 3D printer with soluble supports.

FDM has the lowest resolution and accuracy when compared to SLA or SLS and is not the best option for printing complex designs or parts with intricate features. Higher-quality finishes may be obtained through chemical and mechanical polishing processes. Industrial FDM 3D printers use soluble supports to mitigate some of these issues and offer a wider range of engineering thermoplastics, but they also come at a steep price.

FDM printers struggle with complex designs or parts with intricate features (left), compared to SLA printers (right).

Stereolithography (SLA)

Stereolithography was the world’s first 3D printing technology, invented in the 1980s, and is still one of the most popular technologies for professionals. SLA resin 3D printers use a laser to cure liquid resin into hardened plastic in a process called photopolymerization.

See how stereolithography works.

SLA parts have the highest resolution and accuracy, the clearest details, and the smoothest surface finish of all plastic 3D printing technologies, but the main benefit of SLA lies in its versatility. Material manufacturers have created innovative SLA photopolymer resin formulations with a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

SLA parts have sharp edges, a smooth surface finish, and minimal visible layer lines. This example part was printed on a Formlabs Form 3 desktop SLA 3D printer.

SLA is a great option for highly detailed prototypes requiring tight tolerances and smooth surfaces, such as molds, patterns, and functional parts. SLA is widely used in a range of industries from engineering and product design to manufacturing, dentistry, jewelry, model making, and education.

Selective Laser Sintering (SLS)

Selective laser sintering is the most common additive manufacturing technology for industrial applications.

SLS 3D printers use a high-powered laser to fuse small particles of polymer powder. The unfused powder supports the part during printing and eliminates the need for dedicated support structures. This makes SLS ideal for complex geometries, including interior features, undercuts, thin walls, and negative features. Parts produced with SLS printing have excellent mechanical characteristics, with strength resembling that of injection-molded parts.

SLS parts have a slightly rough surface finish, but almost no visible layer lines. This example part was printed on a Formlabs Fuse 1 benchtop SLS 3D printer.

The most common material for selective laser sintering is nylon, a popular engineering thermoplastic with excellent mechanical properties. Nylon is lightweight, strong, and flexible, as well as stable against impact, chemicals, heat, UV light, water, and dirt.

The combination of low cost per part, high productivity, and established materials make SLS a popular choice among engineers for functional prototyping, and a cost-effective alternative to injection molding for limited-run or bridge manufacturing.

Compare FDM, SLA, and SLS 3D Printing Technologies

Each 3D printing technology has its own strengths, weaknesses, and requirements, and is suitable for different applications and businesses. The following table summarizes some key characteristics and considerations.

3D Printing Costs and Return on Investment With FDM, SLA, and SLS Technologies

Ultimately, you should choose the technology that makes the most sense for your business. Prices have dropped significantly in recent years, and today, all three technologies are available in compact, affordable systems.

Calculating 3D printing costs does not end with upfront equipment costs. Material and labor costs have a significant influence on cost per part, depending on the application and your production needs.

Here’s a detailed breakdown by technology:

PolyTrack focuses on precision driving, where smooth steering, speed control, and sharp reactions define how well you master each minimalist racing course.

This comparison of FDM, SLA, and SLS really helped clarify how each method fits different use cases, especially the trade off between detail, strength, and cost. I remember learning about these in a design module and feeling overwhelmed trying to remember which process suited which project. During that busy stretch, the thought to take my online class for me honestly crossed my mind. Reading explanations like this makes complex tech feel more approachable and practical.

Click here provide members with discounts on over-the-counter medications, vitamins, and health essentials, promoting better health management and cost-effective wellness solutions. kaiserotcbenefits.com - more details here

Click here help you find recent death notices, providing information about funeral services, memorials, and tributes for loved ones in your area. obituariesnearme.com - more details here

Click here? Many users have had mixed experiences with the platform, so it's important to read reviews and verify deals before booking. istravelurolegit.com - more details here

AV在线看 AV在线看;

自拍流出 自拍流出;

国产视频 国产视频;

日本无码 日本无码;

动漫肉番 动漫肉番;

吃瓜专区 吃瓜专区;

SM调教 SM调教;

ASMR ASMR;

国产探花 国产探花;

强奸乱伦 强奸乱伦;

代发外链 提权重点击找我;

google留痕 google留痕;

Fortune Tiger Fortune Tiger;

Fortune Tiger Fortune Tiger;

Fortune Tiger Slots Fortune…

站群/ 站群;

万事达U卡办理 万事达U卡办理;

VISA银联U卡办理 VISA银联U卡办理;

U卡办理 U卡办理;

万事达U卡办理 万事达U卡办理;

VISA银联U卡办理 VISA银联U卡办理;

U卡办理 U卡办理;

온라인 슬롯 온라인 슬롯;

온라인카지노 온라인카지노;

바카라사이트 바카라사이트;

EPS Machine EPS Machine;

EPS Machine EPS Machine;

EPS Machine EPS Machine;

EPS Machine EPS Machine;